Before you Build | Getting Started

Planning to build with reclaimed wood but still need more information?

Here are 5 steps from choosing wood to production

TO RECLAIM OR NOT?

Get clear on whether you want to use reclaimed timber or just timber.

Reclaimed wood isn't as convenient to buy as warped wood, but then again nothing matches reclaimed wood's uniqueness and character. Being reclaimed, our wood is a unique product full of character and "imperfections" that adds to the flavour and richness of any building. Each installation holds a history, and being a natural product, will vary in grain, texture and coloring. Our wood is salvaged from misused structures, so expect it to contain bolt holes, seasoning checks, patina and natural erosion which enhances the natural beauty of the wood.

If you are looking for a uniform product devoid of unique characteristics, you are probably not looking for reclaimed timber. Likewise, if budget is you highest priority this also isn't for you as reclaimed timber is generally more expensive.

However, if you want to build a structure that will last and will not need to be replaced for many years due to rot or termites, then Kaltimber's reclaimed woods can save you money in the long term.

Think of it as an investment!

Now that you have decided to use reclaimed wood, let’s have a look at the products themselves.

PRODUCT DESCRIPTIONS & SPECIFICATIONS

Decide on specific products and what do you need them for.

Do you want to build your whole house out of reclaimed timber? Do you just want certain elements such as the floor, deck, posts?

Feel free to visit our products section from the main navigation to get a better idea of what standard products we carry and contact us for any additional questions.

Get a bill of materials from your architect/contractor which outlines the dimensions and specifications for each product you require and send us an e-mail.

Now that you have a clear idea of what you are looking for and an approximate quantities and dimensions it’s time to meet!

INITIAL CONSULTATION

Come and meet with us for an initial consultation along with your project team. In this meeting we will discuss the look and feel your project is aiming for, the timing, as well as the specifics of each product, including timber qualities, application, finish, dimensions and quantities.

We will try to match our product to your specifications to reduce waste in-line with your engineer's structural specifications.

This meeting will take place at Kaltimber's office/showroom, where standard samples are available to view or for purchase.

Now that you have provided us with specifications we can prepare your quote.

QUOTE

Kaltimber quote will be based on the specifications you provided, according to what was discussed as well as what we have in stock.

This quote includes: dimensions, specifications, finishing, payment terms and other policies and the price.

Now that everything is clear on your quote, it is time to produce!

PRODUCTION

Once we receive the signed invoice with a 60% deposit, we will begin to process your order according to factory schedule. We only keep a limited quantity of ready to use stock on our shelves. Most of our products are made to order and require some degree of processing. Production times are dependent on each order and will be discussed at the quote stage.

All the production is made in house as we own all the machinery needed. We do not use third party therefor control all the production and can ensure consistent quality.

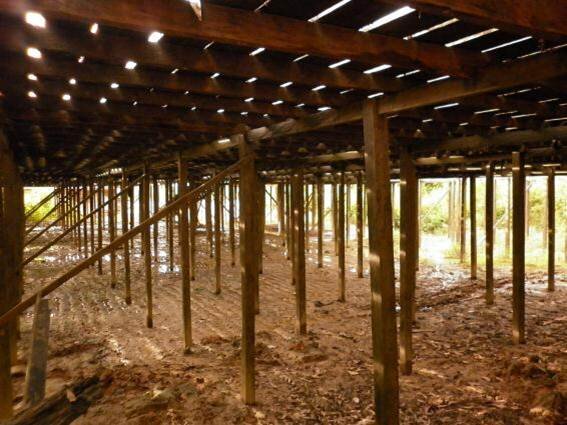

Rustic natural top face decking reclaimed from a building in East Kalimantan

Top 10 questions to ask

when buying wood flooring

1. Which type of wood floor is right for me, solid or engineered?

That depends on where you want to install it. Both solid and engineered wood floors are made using real wood, so both are environmentally friendly.

Solid wood flooring is exactly what the name implies: a solid piece of wood from top to bottom. The thickness of solid wood flooring can vary, but generally ranges from 1.8cm to 2.2cm. Solid wood can be used in any room that is above grade (above ground). One of the many benefits of solid wood flooring is that it can be sanded and refinished many times. Solid wood floors are ideal in family/living rooms, dining rooms, bedrooms, and even kitchens and powder rooms. About the only place you can’t use solid wood flooring is in the basement, but there’s a solution for that area too.

Engineered wood floors are real wood floors that are manufactured using multiple layers of wood veneers. The layers that you can’t see can be of the same species, or of different species. The grain of each layer runs in perpendicular directions, which makes it very dimensionally stable. This means that the wood will expand and contract less than solid wood flooring during fluctuations in humidity and temperature.

Engineered floors can be nailed or stapled to a wood subfloor, or glued down to a wood or concrete subfloor. This makes engineered wood floors ideal for slab and basement installations, but they can be used in any room above, on or below grade. While this type of flooring can be sanded and refinished, it cannot be done as many times as solid wood flooring.

2. Which wood species is right for me?

Choosing the right species of wood flooring for you is strictly a matter of your style, budget and personal preference.

Do you like light woods like teak? These species generally make a room appear more open and airy.

Do you like medium woods like bangkirai? These species generally make a room appear more warm and cozy.

Do you like darker woods like ulin? These species generally make a room appear more stately and refined.

Finishing can offer even more color options.

Once you decide on a look, you should consider how your floors will be used. Are you a retired couple living alone, or a busy family with young children and pets? Each wood species is rated for its hardness and durability using something called a Janka scale (the Janka scale gives a good indication of how likely a wood is to dent or show other wear).

3. Is a factory-finished floor or a site-finished floor better for me?

Each method has its own benefits and advantages, and choosing the right method will depend on the level of customization you want to achieve, and your personal preference.

A job-site finish is one that applied on the job site, in the room where the flooring is being installed. With a job-site finished floor, you can choose the type of finish to be applied to your floor, which will impact maintenance, as well as the stain, if any, and sheen of the final product. In other words, a job-site finished wood floor offers you unlimited possibilities for customizing the final appearance of your floor.

However, because your floors will be sanded and finished in your home, you should expect noise, dust, and some disruption to your home. In the past few years, many dust containment systems have been developed to help control dust and debris, so be sure to ask your contractor if one can be used for your installation. You also will need to allow time for the finish to dry on-site, during which time you will not be able to walk on your floor.

With factory-finished wood floors, the finish is applied at the factory, long before it reaches your home. While many options are available with factory finished floors, you will not be able to achieve the same level of customization as you can with job-site finished wood floors.

A major benefit of factory finished floors, however, is that there is minimal dust and noise during the installation process. You also will be able to walk on your floors immediately after they are installed.

4. My room is 40 square meters, but we’re being told to order 44 square meters of flooring. Is this really necessary?

Yes. As a general rule, you should plan to order 10% more flooring than is needed for the installation. Much of the material will be cut to fit the exact space, and once the boards are cut, they likely cannot be used elsewhere in the room because the end tongue or groove will have been removed. Once that happens, that board can no longer adjoin with another board, so there is some waste involved.

You may need to order slightly more or less depending on the room. For example, if you need to work around stairs, a bay window, a fireplace, and a closet, you may need to have more than 10%, but if the room is square with no interruptions, less than 10% may work. Your contractor is your best resource for helping you estimate the material that will be needed to complete the job.

Feel free to contact us to get in touch with a professional installer.

5. I’ve seen different finish sheens on wood floors; some are shiny and some are not. Which is better?

It really is a matter of preference. If you choose to install a site-finished floor, you can choose any sheen that you like. Gloss finishes offer the most shine, and will reflect the most light. Semi-gloss finishes offer some shine, and will reflect some light. Satin or matte finishes offer the least shine, and will reflect the least light.

Generally speaking, the less sheen, the less you will notice small scratches and other wear that is normal with wood floors. If you choose to install a factory-finished floor, you will be limited to the sheen available for the material you select. All sheens will offer the same protection for your floor, so it truly is a matter of which look you like best.

6. I’m concerned about pets scratching my floors. Is there anything I can do to prevent this?

There are several things you can do to minimize scratches from pets on your wood floors. Place scatter rugs at all doors to minimize the amount of dirt and grit being tracked in, especially if your pet likes to dig. Your best defense, however, is to trim your pet’s nails regularly. If scratches occur, as they might whether pets live in the home or not, keep in mind that the scratches most likely will be in the finish only, and not in the wood. If this situation occurs, consult with a professional wood flooring contractor for specific recommendations about how to repair the scratches, and minimize them in the future.

Feel free to contact us for any further questions.

7. How do I keep my floors looking new?

All hardwood floors should be cleaned regularly. To accomplish that, simply sweep, dust mop or vacuum the floors with the beater bar turned off to remove dirt and grit from between the floor boards.

Avoid using a wet mop or steam mop on hardwood floors as water and steam can dull the finish, or even damage the wood over long periods of time.

Place throw rugs at all entrances, avoiding those with rubber backs, which can discolor wood floors.

Special rug mats can be purchased from a wood flooring retailer that will protect the floors from discoloration. Throw rugs will help keep outside dirt and other debris from scratching the floors. Scratches also can be prevented by placing floor protector pads on the bottoms of the legs of any furniture that comes into direct contact with the floors.

When spills occur, be sure to clean them immediately with a dry or slightly damp cloth. Allowing spills to remain on the wood floors could damage the finish, and possibly the wood. Avoid walking on the floors with sports cleats or high heel shoes that are in disrepair. These can scratch the finish, or even dent the floor.

Finally, when the floor begins to look a little dull, use a wood flooring cleaner recommended by your installer to renew the luster. Be sure to use the product as directed, and use only products that are compatible with your wood floor as using the wrong type of cleaning product could damage the finish, and possibly damage the wood as well.

8. How long after I order my floors will it take before they are installed?

That depends. Site-finished floors will take longer to install than factory-finished floors since the finish needs to be applied, and dry, on site.

Depending on the type of finish used, you can expect that there will be multiple coats applied, and that each coat will need to be sanded before the next coat is applied, and also will need to dry thoroughly before the floor can be walked on. In addition, all wood flooring, whether job-site finished or factory-finished, will need to be delivered to the job site and allowed to acclimate for a period of time before the installation can begin. This can take several days depending on the material being used.

This is a very important part of the installation process because the wood must reach equilibrium moisture content (EMC) with the job site conditions to ensure a long-lasting, high-quality installation.

9. I’ve seen instances where wood floors fade over time. Is there anything I can do to prevent this?

Wood floors are one of the few flooring options that become more beautiful with age. Like all natural things that experience change over time, wood floors will experience subtle color changes as they age. This is a natural process that will add to the beauty and character of the floor.

Different species of wood flooring will experience color changes at different rates. These changes are natural, but can be minimized with a little prevention.

Two factors influence color changes in wood floors: sun exposure and the finish that is applied to the floor. Over time, prolonged sun exposure will cause wood floors to change color. Think about how skin reacts when exposed to sunlight. Wood reacts in much the same way, and you can minimize this effect by periodically moving rugs and furniture to limit that exposure.

The second factor that can cause wood floors to change color over time is the finish used. Oil-modified finishes will amber over time, giving the floor a slightly yellow appearance. In contrast, water-based finishes generally will remain clear over time, minimizing long-term color changes.

10. Installation is so expensive. Why can’t I just do it myself?

Installing wood floors is a lot more complicated than painting your walls or replacing the hardware on your kitchen cabinets!

First of all, you will be spending several thousand dollars on material alone, so if you damage it, it’s not as easy as buying another $30 gallon of paint or $200 of hardware and starting over again. Plus, wood flooring requires special tools that you will likely have to rent and will have little experience using.

More importantly, however, you will need to make sure the room you’re working in is flat, that the subfloor material will work for wood flooring, and that no moisture issues are present that will damage the wood long-term. Testing for moisture requires special tools as well, and you must test both the subfloor and the flooring to ensure a successful installation.

In addition, you will need to know how to center the room, how much space should be left for expansion gaps, how to work around obstructions like closets, fireplaces, bay windows, staircases, and cabinets, and if you make cutting mistakes, you may end up running short on your material and not have enough to finish the job.

In some cases, you may not be able to exactly match the lot, much like running short of paint sometimes results in a slight color difference when mixing a new gallon.

The bottom line is that installing wood floors is not recommended as a DIY project. In the long run, you will save money and time by using a professional.

Feel free to contact to get in touch with a professional installer.