How Reclaimed Wood Helps Reduce CO2 Emissions

Lumber prices: from gold standard to affordability?

Is reclaimed wood expensive?

How To Spot Fake Reclaimed Wood

What are eight features and benefits of wood flooring

Hardwood and Softwood, what is the difference?

Hardwood is not necessarily a harder material (more dense) and a softwood is not necessarily a softer material (less dense).

Different types of construction projects call for different kinds of timber, both hardwood and softwood are used for everything from structural to decorative.

Softwood and hardwood are distinguished botanically in terms of their reproduction, not by their end use or appearance. All trees reproduce by producing seeds, but the seed structure varies.

Softwood trees are known as a gymnosperm. They reproduce by forming cones which emit pollen to be spread by the wind to other trees. Pollinated trees form naked seeds which are dropped to the ground or borne on the wind so that new trees can grow elsewhere.

A hardwood is an angiosperm. Angiosperms usually form flowers to reproduce. Birds and insects attracted to the flowers carry the pollen to other trees and when fertilized the trees form fruits or nuts and seeds.

The hardwood/softwood terminology does make some sense. Evergreens do tend to be less dense than deciduous trees, and therefore easier to cut, while most hardwoods tend to be more dense, and therefore sturdier. In practical terms, this denseness also means that the wood will split if you pound a nail into it. Thus you need to drill screw or bolt holes to fasten hardwood together. But structural lumber is soft and light, accepts nails easily without splitting and thus is great for general construction.

To sum up

Hardwood tend to be darker, heavier, more expensive, last several decades, naturally resistant to weather.

Softwood tend to be lighter in color, lighter weight, cheaper, last for a decade or so and can be weather resistant but needs to be treated.

Reclaiming or not reclaiming

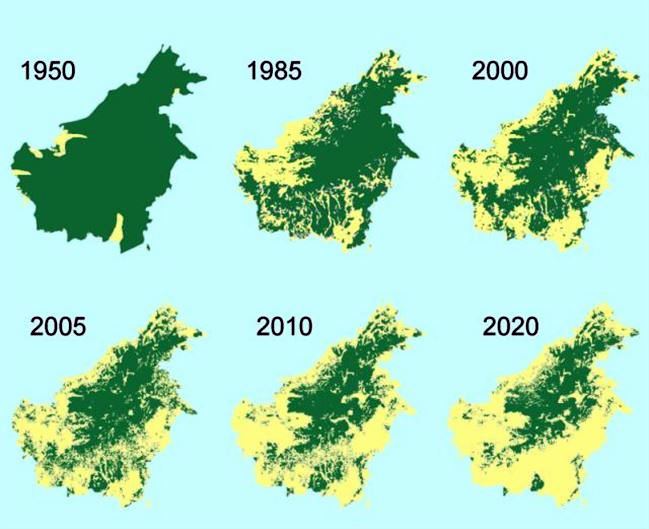

Indonesia is a treasure chest of biodiversity; it is home to between 10 and 15 per cent of all known species of plants, mammals and birds. Orang-utans, elephants, tigers, rhinoceroses, more than 1,500 species of birds and thousands of plant species are all a part of the country's natural legacy.

The mass destruction of Indonesia's rainforests and carbon-rich peat lands threatens this and is the main reason why Indonesia is one of the world's largest emitters of climate changing greenhouse gases.

The lives of millions of Indonesians who depend on the forests for food, shelter and livelihoods are also changing beyond recognition as the forest disappears.

This destruction also threatens our wider world; peatlands are perhaps the world's most critical carbon stores, and Indonesia's peatlands are vast, storing about 35 billion tones of carbon. When these peatlands are drained, burned and replaced by plantations, carbon dioxide is released and the conditions are set for devastating forest fires, which were responsible, for instance, for Singapore's "haze wave" in 2013.

In Kaltimber we aim to provide 100% reclaimed wood by knowing the origin of all our stock.

New owner

As per December 1st 2016 Kaltimber goes back in business!

On January 1st 2017, Kaltimber will resume its activities on decking, flooring, paneling, counter-top and other B2B oriented objects (in-house design or custom design).

Our production team; still is the same so you will continue to find this unique quality Kaltimber has to offer.

Our sourcing team; still is the same so you will continue to find quality reclaimed hardwood from ethical and legal sources.

Our sales team; still is the same so you will continue to find precise and professional information, quick reply and this forever smile.

We are looking forward to meet all of you to discuss and assist you on your projects, no matter how big or small they are.