5 Wooden Subflooring Installation Mistakes You Must Avoid

What are eight features and benefits of wood flooring

A look beyond the promise and assurance of wood flooring - Part 1/2

Adherence to expectations is equally essential with huge purchases like flooring. This is quite true when dealing with hardwood floors. It is without a doubt that a new hardwood floor will incorporate a facet of aesthetic and warmth to your home. A lot of customers do not have an idea that wood flooring possesses extraordinary features that make it not the excellent choice for everyone.

Scratch on flooring

This article, which is based on two parts is by no means meant to discourage you from purchasing a hardwood floor, but you do require taking into considerations these four excellent facts in relation to hardwood floors before buying it:

I. Wood Floors are prone to scratches.

There are several finishes that manufacturers put on wood flooring in order to make them scratch resistant. The most famous finish to this date is Aluminum Oxide. Wood Flooring also pairs with a wear warranty ranging from five to fifty years. Wear warranties, however, basically only guarantee that the veneer of wood will not completely wear through. You cannot find ant-scratch warranties in the wood industry. All wood floorings, regardless of what the finishing or the wood quality is, will be prone to scratch. That being said, you have to ensure to prepare your home for a wood floor prior to installing. It is an excellent idea to utilize furniture protectors, area rugs, floor mats in guarding your wood against scratches. To add, you might want to mull over installing tile in your passage ways, since it is the busiest area in terms of traffic. If there are huge children or pets in your house, you have to consider laminated flooring which is more resistant to scratches.

II. There is a guarantee that wood flooring will Indent.

Wood floors are regarded as soft product, but they are prone to denting from drops or heavy use. No wood flooring is dent-proof, but several classes of wood have several hardness degrees as well. The Janka test is utilized to know the hardness or softness of wood specie. Using this kind of test, wood species are supplied a score in terms of a force needed to embed a steel ball into the wood itself. It is known that the higher the score, the better the wood is in terms of resisting wear and dents. Northern Red Oak, the standard class of wood utilized in flooring, is the basic to which all other classes are measured against. It possesses an all-time score of 1290. There are certain classes that have a score of more than 3000 and while they wear better in terms of everyday use, they will still dent at some time, subjected to a heavy drop of load. If you are really paying attention to your floors ability to withstand dents, you can resort to other options. There are “wood-like” porcelain and laminated products that are high-pressure and a lot more resistant to wear and tear. To add, a hand scraped or distressed wood floor will perform an excellent job at hiding dents and other types of wear on your floor.

Wooden nail

Hardwood nails

There haven’t always been iron and steel nails to use in construction. Long before nails and screws were widely available, most construction – whether it was furniture, ships or building construction – made use of wooden nails and pegs. Even now, construction using wooden nails, dowels and pegs is a hallmark of quality.

Wooden joins like those that use wooden nails are preferable to metal nails and screws in construction that will be exposed to the elements. The reason is a simple one – a rusted nail contributes to rotting wood, weakening the construction. A securely fastened join using wooden nails is stronger and lasts longer than most metal and wood construction.

There are a number of construction firms that specialize in timber frame construction of cabins and cottages, using all wood joins, including wooden peg and wooden nails as fasteners.

The idea of fastening wood together using wood may seem strange to anyone that’s not a woodworker or cabinet maker. After all, what else is a hammer and nails for? Or a screwdriver and drill and screws? Any fine furniture maker can tell you different, though. The use of mortise and tenon, dovetail and wooden nails joining methods are all common methods that go back far into history – and are still used NOT for historical accuracy, but because they are simply the better way to hold wood together.

Wooden nails are made from dowels, generally a hardwood. They’re often pre-shaped with a rounded or tapered tip to make insertion easier. They may be smooth or grooved to hold glue better, and they are available in many different lengths. The finished quality of your furniture can’t help but be affected by the quality of the wooden nails used in its construction.

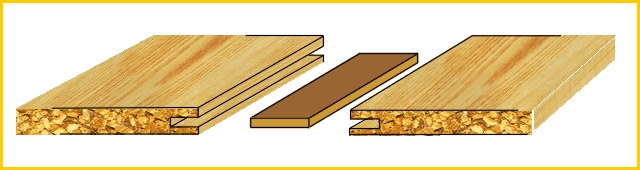

Joinery, what is a tongue-in-groove?

Tongue-in-groove is similar to tongue and groove, but instead of the tongue forming part of one of the edges, it is a separate, loose piece that fits between two identically grooved edges. The tongue may or may not be of the same material as the grooved pieces joined by the tongue.

New finishing available / Semi-smooth

First successful try at a new type of finishing, the semi-smooth. Enjoy the beauty of the inner Ulin while keeping a touch of its original look.

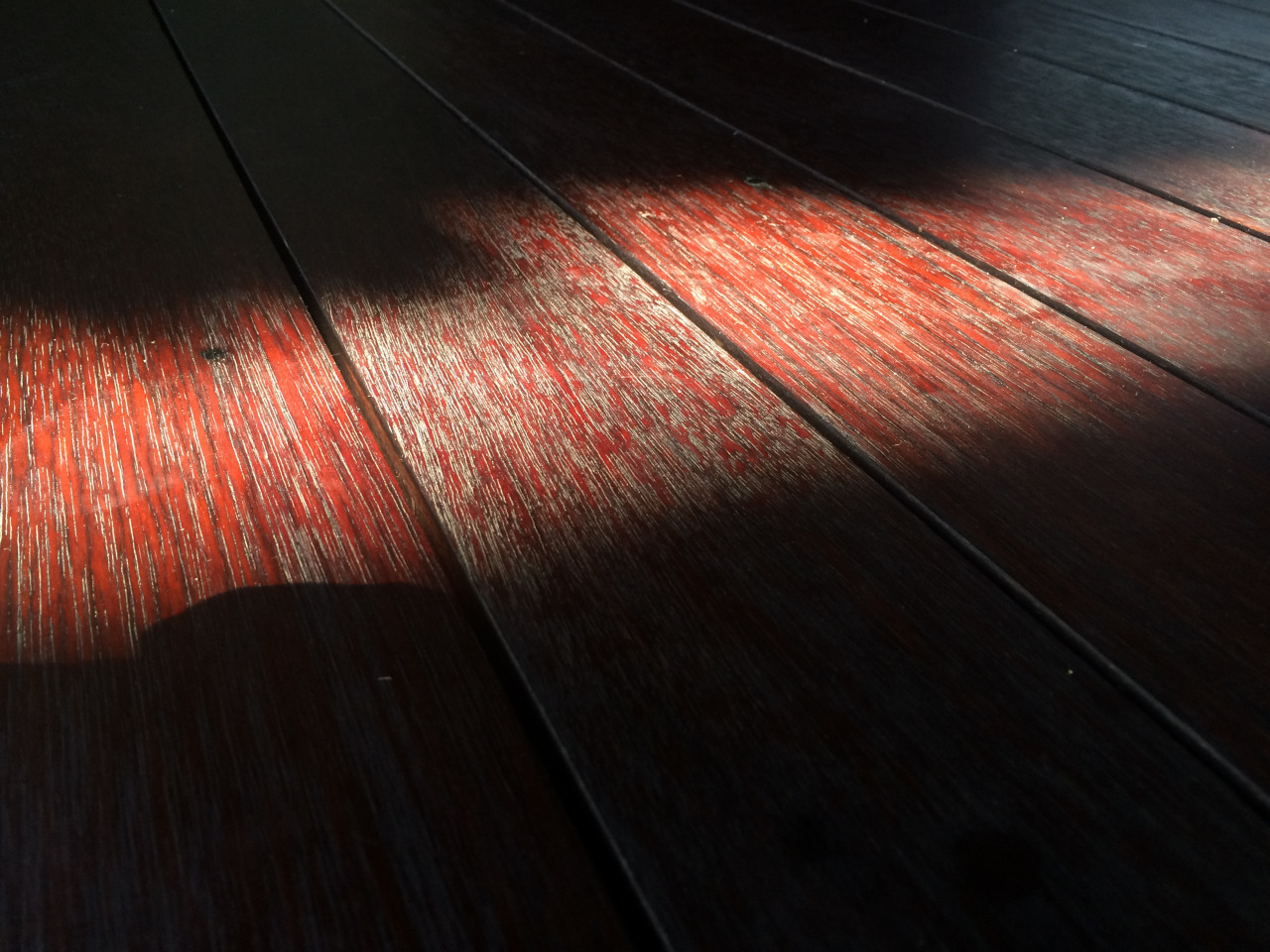

Protect your tropical wood deck from weather

Why seal my wood?

As you can see on the picture, nature can have a disastrous effect on your exterior wood. The natural effects of the sun and water will cause graying, fading, mildew, cupping, splintering, cracking and warping.

This is why it is necessary to seal your exterior wood. Properly sealing the wood will prevent water from seeping into cracks which causes cracking, cupping, bowing, and splintering. The UV protectors in our seal greatly reduce the effects of the sun, such as cracking, drying, and graying.

Wood is also, in many ways, a living, breathing thing. Wood expands and contracts when it is cold or hot. Wood needs to breathe and it also needs to be protected properly from the elements.

When should I have my deck sealed?

Anytime of the year is a good time to have your wood protected. You can ask us for advice.

Should I seal the wood myself?

Sealing your own deck may seem easy enough, but many times homeowners create irreversible damage to their deck. Not pressure washing properly, using a corrosive chemical on your deck, or using the wrong sealant can be disastrous, and your deck can NEVER be repaired 100%. Considering the fact that most sealants only last 6 months to a year, you are the stuck with the predicament of what to do then. Do you have to strip it all off using strong chemicals? Or should you recoat over existing faded seal, which will not give your deck a uniform look? Or you could wind up paying a professional a much higher fee to repair the damage. The best solution is to have it done properly the first time. For that also feel free to ask us and we’ll be pleased to assist and guide you.

New owner

As per December 1st 2016 Kaltimber goes back in business!

On January 1st 2017, Kaltimber will resume its activities on decking, flooring, paneling, counter-top and other B2B oriented objects (in-house design or custom design).

Our production team; still is the same so you will continue to find this unique quality Kaltimber has to offer.

Our sourcing team; still is the same so you will continue to find quality reclaimed hardwood from ethical and legal sources.

Our sales team; still is the same so you will continue to find precise and professional information, quick reply and this forever smile.

We are looking forward to meet all of you to discuss and assist you on your projects, no matter how big or small they are.

Wooden floors have a timeless quality

Wooden floors have a timeless quality that can change the whole look and feel of a building. We all love wooden floors, but what do we need to be aware of when shopping for flooring to get the best results?

Living in the wet tropics, one of the main considerations we need to be mindful of is the effects of moisture on wood in our construction. Wood floors are no exception. All wood has a moisture rating which changes as the temperature and moisture in the air increases and decreases with the seasons. Wood is a natural product so it expands and contracts in response to these changes.

The general and very simple rule of thumb with wood flooring is never put solid wood flooring in wet or moisture-susceptible areas: water and wood do not mix. This includes in areas that are below grade such as basements or cellars. Water degrades wood, and constant or prolonged expose can cause cracks, cupping and buckling.

The method you use for floor installation will depend on how and where you are installing your floor. The three common installation sites are described as below grade, on grade or above grade. For floors at the on-grade or ground level, it is common to nail or screw the boards onto small battens which have been nailed or screwed into a concrete subfloor. This is all fine, but remembers to seal your concrete slab with plastic sheeting first to prevent the enemy of the wood floor, rising damp. Just like we can take steps to build out termites, we can also take steps to eliminate moisture intrusion. Sealing your concrete slab should be a standard building practice in the wet tropics, but unfortunately this is not the case hence you will need to request this specifically.

For floors at the above grade level, commonly the flooring will rest on floor joists which are sitting on bigger beams known as bearers. A floor that rests on joists as opposed to on battens or one that is glued directly onto the floor is known as a ‘floating floor’. It is a good idea to check what kind or structural support you need when shopping for flooring as this cost needs to be calculated to get the final per square meter price.

Some tips on selecting and installing wood floors:

- Ensure your boards finished to an even thickness at a minimum. This will make it a lot easier to install.

- For below and on grade flooring, check the moisture content of the wood prior to installing if possible and make sure there is no possibility of moisture intrusion

- Solid wood flooring shrinks in dry environments and expands in wetter environments and most of the expansion happens along the growth rings (tangentially), and about half as much across the rings (radially). Get flooring which has small grooves on the underside, known as “back relief” to allow for this swelling and shrinkage

- Remember that wide boards tend to expand and contract more than narrow boards

Have fun!