I have touched on this topic before, but really it deserves a book’s worth of attention. Little information is available to Indonesian consumers about wood finishes, and what is out there is by no means comprehensive, clear, or particularly accessible. For those of you with experience in this area, you may have noticed there are limited choices available on the local market. Your average local builder will tend to offer the standard polyurethane-based finished that they know, interchangeably called “plitur” or “Mowilex” (a brand-name). Sometimes a varnish traditionally made from resins called “sirlac” (Shellac) but nowadays made from pulmerised petro-based oils is used for finishing teak. Another product we can pick up in large Indonesian supermarkets is ‘fake’ teak oil, made from to petroleum distillates such as kerosene. The good stuff is usually made with a linseed oil base.

The sheer number of timber finishes available on today’s market can sometimes be a tad overwhelming! In Indonesia we are a way behind some of the European, Australian and American advances in timber finishes, however in recent years more options have become available. I will look at these products in the upcoming issues, but first, let’s look at some basics.

There are four different ways to treat or finish wood: oil, wax, varnish or pigment (paint or stain). The first three don’t add any colour to the wood, whereas pigment does. Let’s look at some pros and cons of the various types.

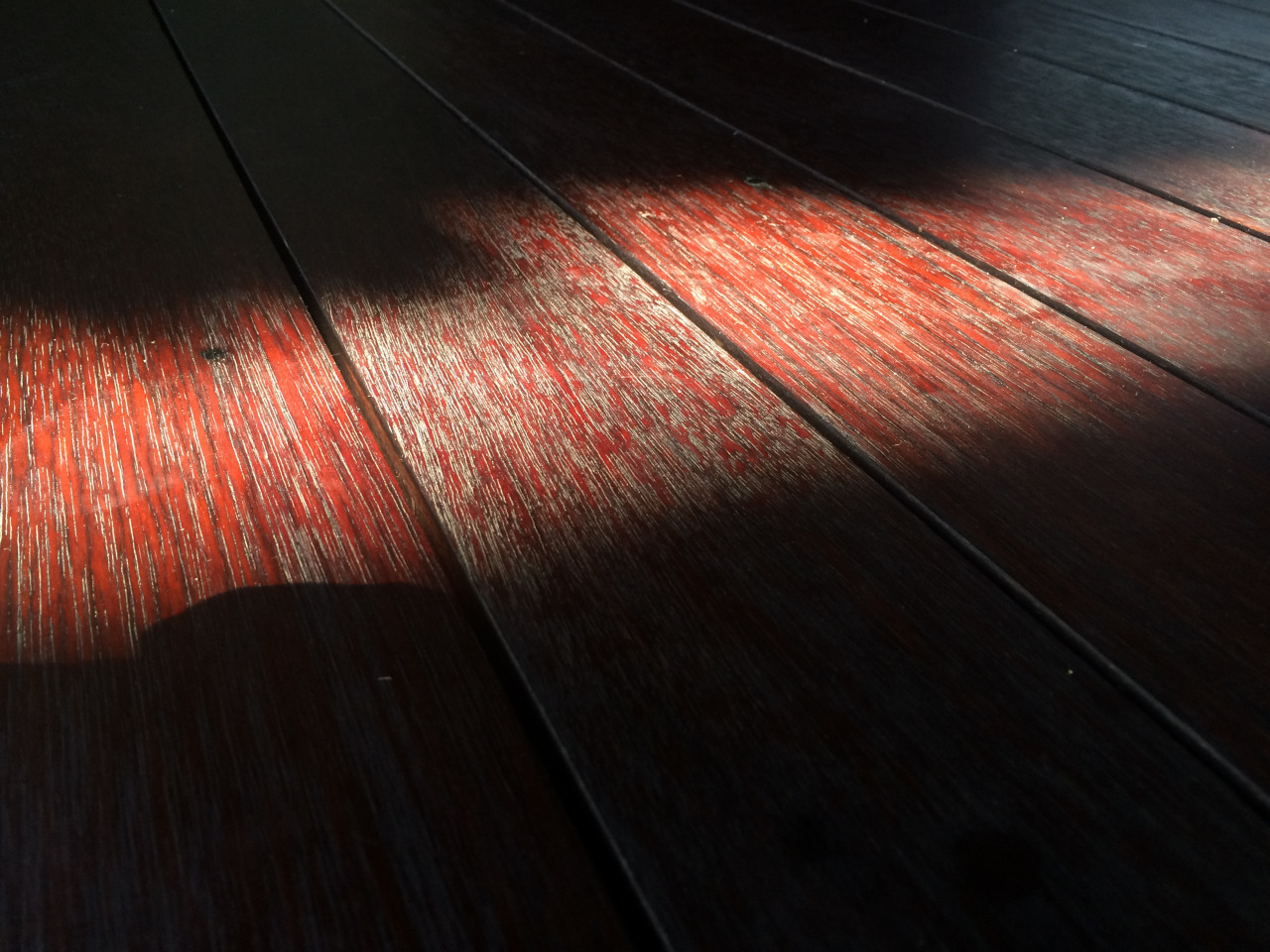

1. OIL

Permeates timber cells and simultaneously seals and protects. Oils are not affected by moisture content fluctuation of wood (they are elastic). Many wood oils are plant-based and hence environmentally sounder. Types include: Unblended Wood Oils (tung, linseed, soy, candlenut, castor), Polymerised Wood Oils (specially processed oils that have been heated to help them dry faster which create a harder surface film and a more durable glossy luster) and Pigment Oil-Based Stains (contain oil which enables the stain to penetrate the wood)

2. Wax

Fills all of the cavities in the wood to achieve an even finish that is polished. Wax doesn not achieve a film on the surface, as oils do. It creates a flat surface which allows you to polish the wood. Many oil finishes benefit from a light liquid wax coating , especially floors.

3. Varnish

Creates a transparent film coating over the entire wood surface. There are penetrating varnishes and non-penetrating varnishes. There are approximately 60-70 different types of varnish out there. In Indonesia there are probably around 10 different kinds, but many different brand names. Types include: Polyurethane Coatings (generally petro chemical-based which are thinned with petroleum distillates to enable easy application. They create a glossy finish and are easy to apply, however have potential health risks as, depending on the brand, they contain a high level of solvents/ chemicals. They can crack and darken over time, and provide a surface coating only, similar to a plastic film). Resin based varnishes made from tree sap.

4. Pigment

There are two kinds of pigment: paint, which puts a non-transparent film over the wood surface, and stain, which colours the wood but leaves the grain exposed. Pigmented Paint will protect wood indefinitely; however it will cover the wood so characteristics are not displayed. Also, some paints in Indonesia contain lead. Environmentally speaking, paints are one of the worst pollutants in the world. The best solution is using timbers appropriately, i.e exterior grade timbers outside, and softer interior grade timbers inside and accept that timbers grey with age as do we.

The type of coating that you use should be determined by timber type, use, desired gloss level or appearance, and your own personal preferences. Of these, there are more ‘natural’ choices and more ‘sythetic’ solutions. Decide on final look first, and then move on to available options.

Stay tuned for the next issue, where I will review wood finishing products available on the Indonesian market. Till next time!