As highlighted by Gideon Fink Shapiro is a great article written for Architect Magazine, “in weighing the options of steel, concrete, or wood, factors to consider include project location, scale, expected service life, reuse potential”.

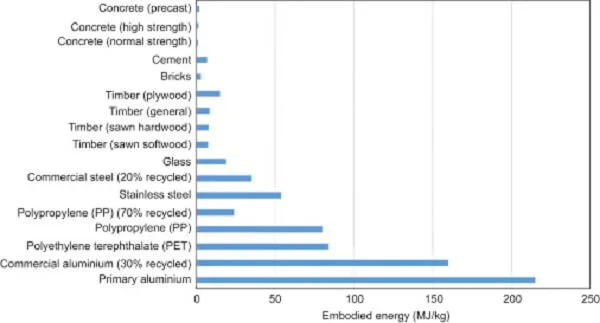

All of the above is included in the many factors used in evaluating the embodied energy of construction materials.

Steel Vs Wood Vs Concrete Embodied Energy

A concrete exampled showed up when travelling around. We saw this clever little bamboo toilet roll the other day and it got us thinking. The standard material for toilet roll holders is metal. After some research, it turned out that steel as a material utilises 16 times more energy by mass than wood, or in this case bamboo.

Clever design right?

We call this “Embodied Energy”. Embodied energy is measured as a quantity of non-renewable energy per unit of building material, either by mass or volume. The science is a tad imprecise, but it stands as a basic launching pad to start looking at the materials we use and what their real ‘cost’ is, from cradle to grave.

You see the ‘embodied energy’ of steel and other metals, or the total energy expended to procure and transport the material, manufacture it into products and then maintain and repair them during their lifespan is very high. Kiln-dried hardwood is far lower by comparison.

Did you ever wonder how much energy could be saved in your own house For example, if you replaced the metal used with wood every time? Instead of steel towel racks, you could use reclaimed wood. Out go the steel soap racks, bring in the wood! There is a lot of thinking to do about the benefits of using lower embodied energy materials. This is particularly true about new constructions.

Reclaimed Ironwood Ceiling

A good example of embodied energy is bamboo blinds, particularly useful as weather barriers to help prevent rain and wind from entering, as it tends to do in the tropics. Bamboo being an organic material, you can replace them relatively cheaply and they will decay and return to the earth. Bamboo is cheap because it is a fast-growing material, its production costs are low, and it is easily renewed. Compare that to plastic sheet roofing, also a relatively cheap material to buy, but its downside is it’s made from fossil fuels and hence has a high embodied energy, and in the harsh tropic environment, it ends up on landfill after 5 or so years and is still there in another thousand years.

Another example we came across was a rot-ridden solid Merbau deck that was only two years old when the owner decided to replace it. Cost considerations had been the major determining factor as it is around 30-50% cheaper than reclaimed ironwood (Ulin). However, Ulin has a Class 1 durability rating, meaning its probable in-ground life expectancy is +25 years. By comparison, Merbau has a Class 3 in-ground durability rating giving it a 5-15 year probable lifespan.

There is no point in using timber species that are not designed for the desired application, not installed correctly, or if it costs the earth. It may seem cheap, but how much does it really cost? Choosing a timber that has a higher up-front cost but lasts 10 times as long makes better economic sense at the end of the day. Maybe, more importantly, the carbon cost of its whole supply chain is way better for our planet.

So the choice of material in your building project is both about the energy used to produce the end product, the relative life span you will get from it, the way you install it, and the local environmental impact its extraction has at the point of origin.

In the meantime, product rating is not widespread in Indonesia, so it is up to us as consumers to do our research. Looking at embodied energy in building materials is a start, and using recycled products wherever possible is an excellent alternative.